BRIDGE DECKS

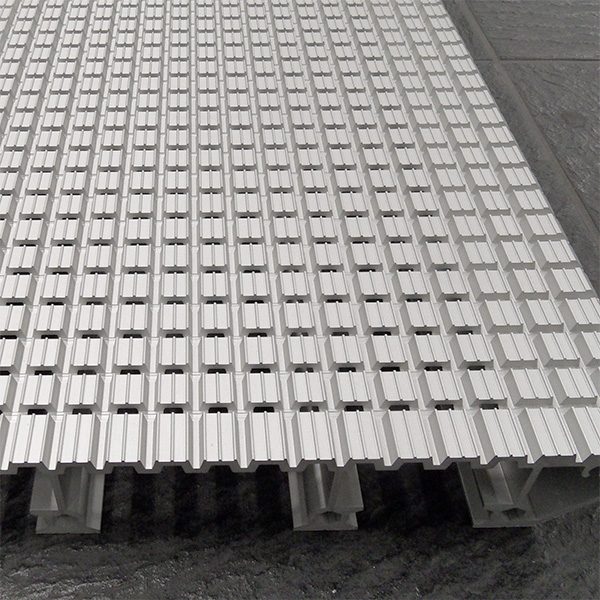

Van Campen Projectmanagment has expertise in aluminium bike and pedestrian bridge decks practically deliverable in any length and width. As a company we limit ourselves to specifically to bike and pedestrian bridges. The assembly of a bridge deck and railing construction consists of extruded aluminium profiles which can be ingeniously connected to each other.

If either necessary or required, the prefabricated elements are provided, in advance, with a wear layer in the colours black / red or other colours. Usually this is done with a two-layer Granito which is glued with an epoxy system onto the deck of the aluminium bridges. An alternate option can be to provide the bridge deck parts with an anti-slip layer, fully integrated into the surface and/or the profiles by means of extrusion or machining.

Aluminium, being such a durable material, does not necessarily have to undergo a surface treatment. This depends on the alloy of choice. In the offshore industry for example, untreated aluminium bridge constructions are used that can withstand the most extreme conditions, including seawater.

The modular aluminium bridges have great advantages over wooden, plastic, composite or steel bridges. After all, due to the freedom in design which profiles provide, the chosen design of an architect can always be fully embodied. Aluminium bridges are very maintenance-friendly. Also, the lifespan of the material is virtually unlimited.

The durable lightweight aluminium bridges are offered turnkey, which implies that the connection to abutments (if any) is incorporated in the construction. The great advantage of a prefabricated bridge deck or platform is that (pre-)assembly takes place in our factory under controlled conditions. As a result, placing such light aluminium bridges is a short-term action, meaning that traffic on location is not hindered for long. Any required traffic measures are kept to a minimum, which reduces costs.

It goes without mention of course that all products meet the set requirements and specifications, as laid down in the Building Code.